Why Oxygen Free Nitrogen (OFN) is Essential for Air Conditioning Purging and Pressure Testing

Ever wondered why your air conditioning system loses efficiency within months of installation, or why a supposedly simple leak test turns into a costly repair job? The answer often lies in what you used, or didn’t use, during the initial purging and pressure testing stages. Using compressed air might seem like a quick shortcut, but it’s setting your entire HVAC system up for premature failure.

Oxygen Free Nitrogen (OFN) isn’t just a recommendation from refrigeration engineers, it’s the only gas that protects your copper pipework, refrigerant, and compressor oil from contamination. When you’re installing or servicing air conditioning equipment, the choice between regular air and nitrogen for air conditioning work determines whether you’re building a system that lasts or creating an expensive problem that’ll need fixing in six months.

What Makes OFN Different from Regular Nitrogen or Compressed Air

Not all nitrogen is created equal. Standard industrial nitrogen might contain trace oxygen, moisture, and hydrocarbon contamination that’ll wreak havoc inside a sealed refrigeration system. Oxygen Free Nitrogen is refined to an extraordinary purity level, typically 99.998% pure with less than 0.5 parts per million (PPM) of oxygen and under 2 PPM of moisture.

Think of it this way: your air conditioning system is like a high-performance engine. You wouldn’t fill a precision gearbox with dirty oil and expect it to run smoothly. The same principle applies here. When you introduce regular compressed air into copper pipework, you’re pumping in roughly 21% oxygen, along with water vapour, oil mist from the compressor, and particulates. That oxygen immediately starts oxidising the copper.

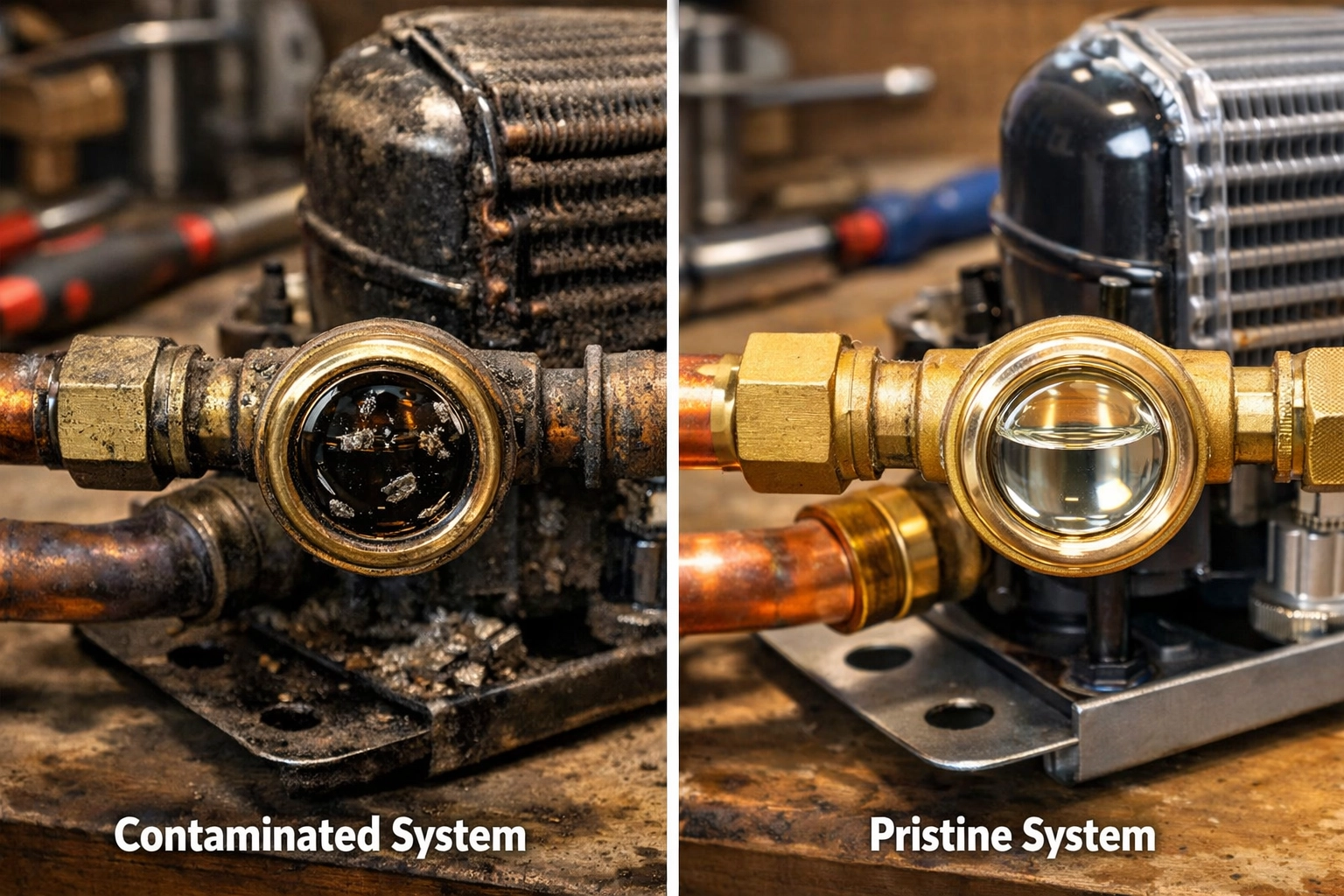

The result? Black copper oxide flakes that break off, travel through the system, and clog metering devices, expansion valves, and filter driers. Once that happens, refrigerant flow drops, cooling efficiency plummets, and you’re looking at a system teardown to clean contaminated components, a job that costs far more than buying the right nitrogen gas bottles in the first place.

Why Copper Oxidation is Your System’s Silent Killer

Copper is the backbone of most air conditioning installations. It’s malleable, thermally efficient, and relatively easy to work with. But expose it to oxygen under heat, such as during brazing, and you’re creating a chemical reaction that forms copper oxide scale on the internal pipe walls.

Those black flakes don’t just disappear. They circulate with the refrigerant, scratching compressor internals, blocking capillary tubes, and contaminating the oil that lubricates moving parts. Over time, this contamination reduces system efficiency, increases energy consumption, and shortens compressor lifespan by years.

The HVAC purging gas you choose during installation is your first line of defence. When you flow OFN through the pipework while brazing, you displace oxygen and create an inert atmosphere inside the pipes. No oxygen means no oxidation, simple as that. The copper stays clean, the system stays uncontaminated, and you avoid callbacks from frustrated customers wondering why their brand-new air conditioner isn’t performing as promised.

Pressure Testing Without the Explosion Risk

Here’s where things get genuinely dangerous. Refrigerant oils and oxygen don’t play nicely together. Under pressure, oxygen can react violently with polyolester (POE) and polyalkylene glycol (PAG) oils commonly used in modern air conditioning systems. We’re talking about potential combustion inside a sealed system, not the kind of risk any competent engineer should take.

OFN eliminates this hazard entirely because nitrogen is chemically inert. It won’t react with oils, refrigerants, or system components, no matter how high the pressure. When you’re conducting leak testing HVAC systems at 30 Bar or more, you need a gas that’s as stable at 300 Bar as it is at atmospheric pressure.

Using compressed air for pressure testing is false economy. Yes, you’ve got an air compressor on site already, but that convenience disappears fast when you’re dealing with moisture condensation inside the pipework or: worse: an oil fire incident that puts your entire project on hold while you deal with insurance claims and HSE investigations.

The Purging Process: Pushing Out Contaminants Before They Cause Damage

Nitrogen purging isn’t just about displacing oxygen during brazing. It’s also the final cleaning step before you introduce refrigerant. After you’ve completed all pipework, brazed joints, and installed the indoor and outdoor units, there’s still debris inside those lines: flux residue, metal filings from cutting pipes, dust from drilling, and moisture from the atmosphere.

A proper nitrogen purge involves flowing OFN through the system at controlled pressure and flow rates, forcing all contaminants out through strategically opened ports. For most domestic air conditioning installations, you’re looking at purging until you achieve zero particulates in the gas stream: usually evident when a white tissue held at the exit port stays completely clean.

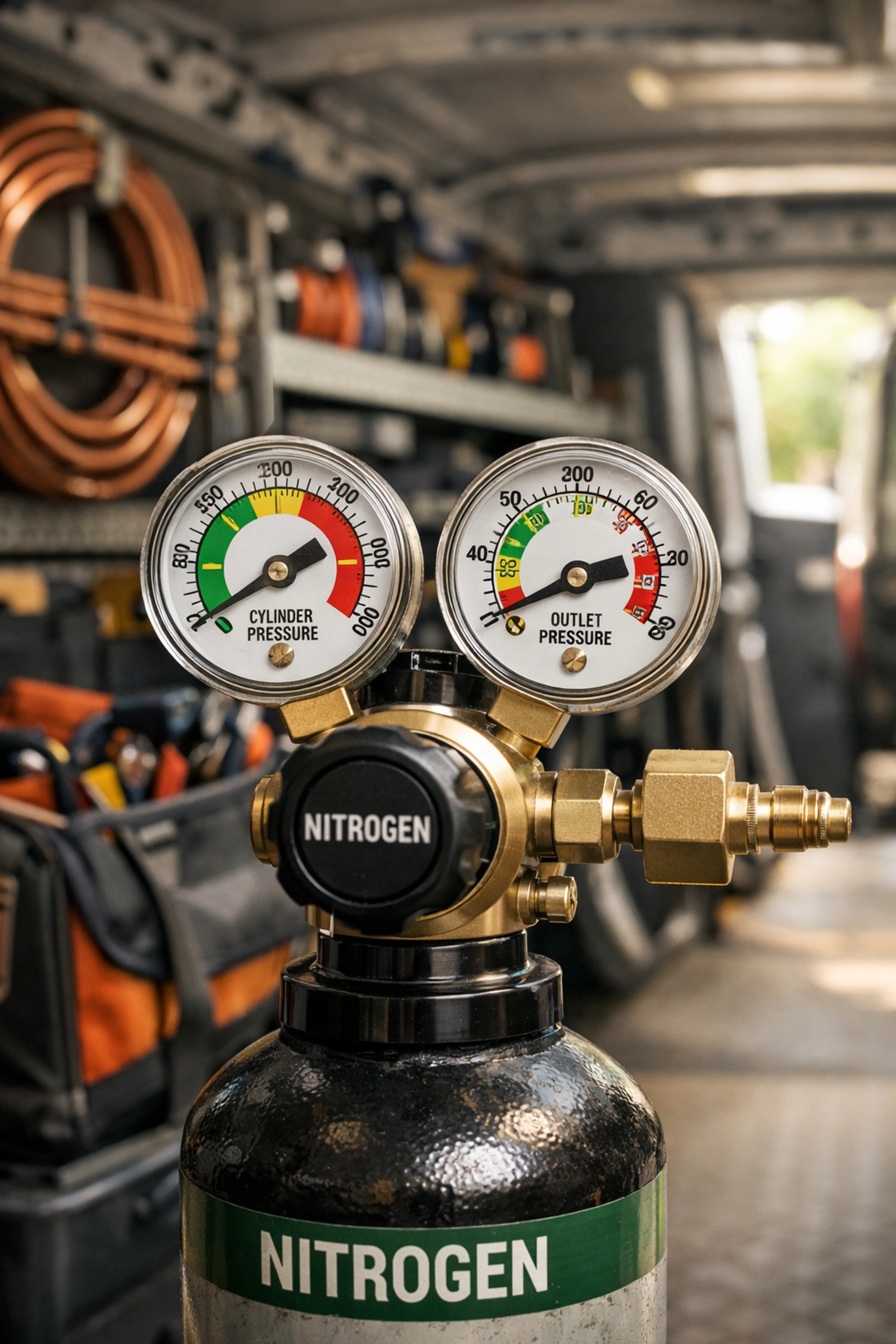

The equipment you use matters here. A decent nitrogen gas regulator gives you precise control over flow rates, typically measured in litres per minute. For small split systems, 10-15 litres per minute is sufficient. For larger commercial installations, you might need 30 litres per minute or more to ensure effective purging across longer pipe runs.

Choosing the Right OFN Cylinder Size for HVAC Work

If you’re a mobile air conditioning engineer, cylinder size becomes a practical consideration. Lugging a 50-litre cylinder up three flights of stairs to install a bedroom air conditioning unit isn’t fun, but running out of nitrogen halfway through a purge is worse.

The 2L nitrogen cylinder at 200 Bar is purpose-built for domestic HVAC work. At that pressure, you’re carrying 400 litres of usable gas in a cylinder that weighs roughly 4 kilograms when full. That’s enough for purging and leak testing two or three typical split system installations, with enough left over for topping up if you need to re-test a joint.

For engineers running larger commercial projects: office buildings, retail spaces, or multi-unit residential blocks: the 10-litre or 20-litre cylinders make more sense. You’re getting substantially more gas capacity without the logistical headache of constantly swapping cylinders mid-job.

The beauty of the deposit-and-refill model is straightforward economics. You put a Deposit the cylinder once and simply refill when empty. No monthly rental fees eating into your profit margins, no contractual obligations, no surprise charges when you decide you don’t need it for a few months. You control the asset, which means you control your costs.

The best part of the deposit system is all the cylinder maintenance if completed by us, we do the safety checks, the cylinder testing when the cylinder is due for retest, all the upkeep is done by the Bottle Gases team.

Real-World Scenarios: When OFN Saves Your Reputation

Picture this: you’ve just finished installing a high-end air conditioning system in a customer’s newly renovated kitchen extension. The installation looks immaculate: pipework neatly clipped, indoor unit perfectly level, outdoor unit positioned for optimal airflow. You pressure test with compressed air, find no leaks, vacuum the system, and charge with refrigerant.

Six weeks later, the customer calls. The system’s struggling to maintain temperature, making odd noises, and the energy bills are higher than expected. You return to site, recover the refrigerant, and find black contamination throughout the system. The metering device is partially blocked, the filter drier is saturated with copper oxide, and the compressor oil looks like it’s been mixed with coal dust.

That’s a complete system flush, replacement of contaminated components, new refrigerant charge, and two days of labour you’re not getting paid for: all because you skipped the OFN purge to save £15 on gas.

Now consider the alternative: same installation, but you flow nitrogen during brazing and conduct a thorough nitrogen purge before vacuuming. The copper stays clean, the system operates at design efficiency, and the customer’s thrilled with performance. You get a five-star review, a referral to their neighbour, and you sleep soundly knowing you won’t be back there fixing avoidable problems.

The Technical Standards You’re Expected to Meet

UK refrigeration engineers work to EN 378 and F-Gas regulations, both of which strongly recommend: and in many professional contexts, effectively require: nitrogen purging and pressure testing for air conditioning installations. While the regulations don’t explicitly mandate OFN by name, they do require that systems be free from contamination and moisture, and that pressure testing be conducted safely.

Using anything other than OFN makes meeting those standards significantly harder. Moisture in compressed air alone can react with refrigerants to form acids that corrode internal components. Even if your system passes initial commissioning checks, you’re leaving a ticking time bomb that’ll fail when the warranty period conveniently expires.

Professional indemnity insurers are increasingly scrutinising installation methods, too. If you’re claiming for a system failure and your installation records show you pressure tested with compressed air instead of nitrogen air conditioner specifications, don’t be surprised when they decline the claim.

Setting Up Your Nitrogen Purging Kit Properly

Getting the equipment right is half the battle. You need more than just a cylinder and regulator: though those are obviously essential. A proper nitrogen purging setup includes:

A regulator capable of handling 300 Bar input pressure with dual gauges showing cylinder pressure and delivery pressure. You want precise control, typically adjustable from 0.5 Bar up to about 30 Bar for different testing stages.

High-pressure hoses rated for nitrogen service, not just generic air hoses. The pressure ratings matter, especially when you’re conducting strength tests at 20-30 Bar. Using under-rated hoses is asking for a dangerous failure.

Flow control valves for managing purge rates. During brazing, you want a gentle flow: just enough to displace oxygen without blowing molten brazing rod across the room. During final purging, you might increase flow to speed up the process.

A moisture indicator or oxygen analyser if you’re working on critical installations. These tools confirm you’ve achieved the necessary purity levels before you close up the system.

The Economics of Deposits vs Renting Gas Cylinders

Let’s talk money, because that’s usually the objection we hear: “Can’t I just rent nitrogen when I need it?” You could, but let’s look at what that actually costs over a year.

Typical rental agreements charge £8-12 per month for cylinder hire, plus delivery fees, plus minimum contract periods. Over twelve months, you’re paying £100-150 just for the privilege of borrowing a cylinder, regardless of how much gas you actually use. Miss a single payment or need to return the cylinder early? Penalty fees start stacking up.

Compare that to buying a 2L OFN cylinder outright. Deposits on the asset immediately. When it’s empty, you pay only for the gas refill: typically £20-30 depending on cylinder size. Use it twice a month and you’re still miles ahead financially compared to rental contracts. Use it daily and the economics become even more compelling.

There’s also the practical advantage of having nitrogen available when you need it, not when the rental company can schedule a delivery. Emergency call-out on a Saturday afternoon? Your cylinder is sitting in the van, ready to use. You’re not explaining to a frustrated customer that you’ll need to come back Tuesday when the gas supplier reopens.

Common Mistakes That Compromise OFN Effectiveness

Even when engineers recognise the importance of nitrogen for air conditioning work, execution often falls short. The most common mistake? Insufficient purge time. You need to flow nitrogen long enough to actually displace all the air inside the system. For a typical 5-metre pipe run, that means several minutes of continuous flow, not a quick ten-second blast.

Another frequent error is using inadequate pressure during leak testing. OFN leak testing HVAC systems should be conducted at or above the maximum working pressure of the system: usually 25-30 Bar for domestic equipment. Testing at 5 Bar might tell you if you’ve got a catastrophic leak, but it won’t reveal smaller leaks that’ll cause slow refrigerant loss over time.

And perhaps the biggest mistake of all: not purging during brazing. Some engineers only think about nitrogen when they reach the pressure testing stage. By then, the damage is done. Every brazed joint made without nitrogen flowing through the pipe has created oxidation inside the system. You can’t purge that contamination out effectively: it’s already bonded to the copper surface.

Making OFN Part of Your Standard Installation Process

The transition to proper nitrogen purging doesn’t require reinventing your entire workflow. It’s about adding two specific steps to what you’re already doing:

First, establish nitrogen flow before you light the torch for brazing. Set your regulator to deliver roughly 0.5-1 Bar, connect to one end of the pipe section you’re about to braze, and leave the other end open. You should feel gentle gas flow at the open end. Now you can braze knowing the internal atmosphere is inert.

Second, after completing all pipework and before evacuating the system, conduct a full nitrogen purge at low pressure. Flow nitrogen through the system at 10-15 litres per minute, monitoring the exhaust with a white tissue until it stays clean. Then increase pressure for leak testing, hold at test pressure for the required time (usually 15-30 minutes), and verify no pressure drop.

These steps add perhaps 20 minutes to a typical installation. In exchange, you’re delivering a system that’ll operate efficiently for its entire design life, with no contamination-related failures and no callbacks eating into your profitability.

Where to Source Quality OFN for Professional HVAC Work

Not all gas suppliers understand the specific requirements of refrigeration engineers. You need a supplier who stocks genuine Oxygen Free Nitrogen cylinders, not someone trying to sell you industrial nitrogen with a vague promise that “it’s probably pure enough.”

Look for suppliers who can provide gas analysis certificates confirming oxygen content below 0.5 PPM and moisture content below 2 PPM. That documentation might seem excessive until you’re dealing with a contaminated system and trying to work out where the moisture came from.

Cylinder availability matters, too. When you empty a cylinder mid-project, you need a refill quickly: same day if possible, next day at worst. Suppliers with proper stock levels and local distribution can provide that responsiveness. Those operating on just-in-time inventory models leave you waiting while they order gas from their own suppliers.

The refill process should be straightforward: drop off your empty cylinder, collect a filled one, pay for the gas. No complicated paperwork, no monthly account fees, no minimum spend requirements. You’re buying a consumable product, not signing up for a financial commitment.

Why Professional HVAC Engineers Choose OFN Every Time

Talk to any refrigeration engineer with twenty years’ experience and they’ll tell you the same thing: they’ve seen too many systems fail from contamination to ever skip nitrogen purging again. The engineers who’ve built sustainable businesses aren’t the ones cutting corners to save a few pounds on gas. They’re the ones who understand that quality installations lead to referrals, repeat customers, and a reputation that commands premium rates.

Using nitrogen air conditioner specifications isn’t just about following regulations or meeting insurance requirements: though those are valid reasons. It’s about professional pride in delivering work that performs exactly as designed, year after year.

When you explain to customers that you’re using Oxygen Free Nitrogen to protect their £3,000 air conditioning system from contamination, they understand they’re working with someone who takes their craft seriously. When you show them the clean tissue after purging, demonstrating zero particulates in the system, that’s tangible proof of quality workmanship.

The choice between compressed air and OFN isn’t really a choice at all: it’s the difference between professional installation and hopeful amateur work. Your customers might not understand the chemistry of copper oxidation or the reaction kinetics of oxygen and refrigerant oil, but they’ll absolutely notice when their system operates flawlessly while their neighbour’s identical unit is back under warranty repair six months later.

Every air conditioning installation is an opportunity to demonstrate your commitment to quality. The equipment you use, the processes you follow, and the attention to detail you bring to every job collectively define your professional reputation. When you open your van and pull out a dedicated OFN gas bottle and regulator, you’re making a statement: this installation will be done right, first time, every time.